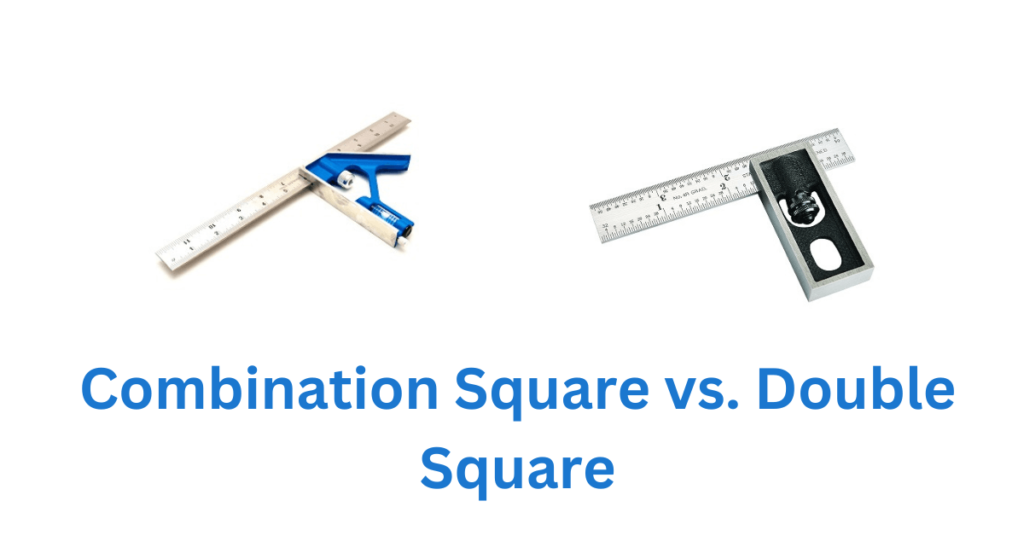

Combination Square vs. Double Square [The Ultimate Guide to Precision]

The combination square and the double square are two essential tools commonly used for precise measurement and planning purposes. This essay will delve deeper into the intricacies of these two measurement tools, thoroughly examining their characteristics, uses, and distinctions. By the end, you will have the ability to differentiate between situations where a double square would be more suitable and situations where a combination square should be used.

The Importance of Precision Measuring Tools in Various Industries and DIY Projects

Precision measurement instruments are essential in various sectors, including construction, carpentry, metallurgy, and engineering. The accuracy of your measurements can significantly impact the success of a project, whether you are a seasoned professional or a passionate DIY enthusiast.

Please take this into consideration: In the realm of fine woodworking, imprecise measurements can lead to poorly fitting joints and incorrect designs. Even a small fraction of an inch discrepancy in construction can potentially result in structural instability. Precision is crucial in engineering and manufacturing as it ensures the production of goods that meet rigorous requirements.

The quality of your measurement instruments can make a significant difference, even in simple home improvement tasks such as assembling furniture or installing shelves. It can determine whether your connections are well-fitted or sloppy.

To ensure accuracy and efficiency in your job, it is essential to have both the combination square and double square in your toolbox. In order to enhance the accuracy and success of your projects, it is crucial to have a clear understanding of the distinctions between various tools. This will enable you to select the most suitable tool for the task at hand. In the following sections, we will explore the advantages of each tool and determine the most suitable situations for their use.

What is a Combination Square?

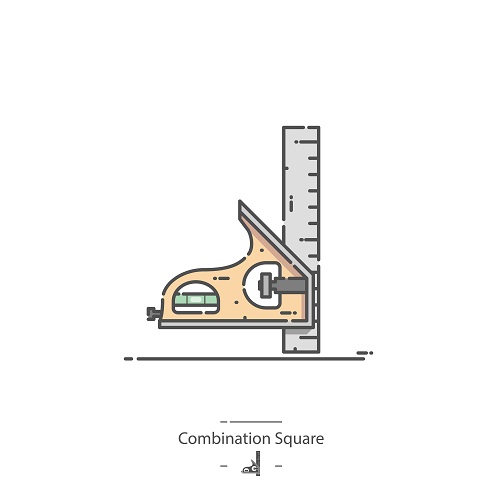

The combination square is a highly versatile tool that is frequently used in a wide range of trades and DIY projects for measuring and marking purposes. The tool is designed to efficiently perform multiple functions in a compact design. The main function of a combination square is to accurately measure and mark 90-degree angles (right angles) and, to a certain extent, 45-degree angles. The tool is crucial for layout work as it guarantees accuracy in tasks such as marking cuts, checking squareness, and creating perpendicular lines.

Components of a Combination Square: Ruler, Square Head, and Center Head

A combination square is usually made up of three primary elements:

- Ruler: A ruler is a slender, flat, and straight tool made of metal or plastic, featuring measurement markings along its length. It is commonly available in different lengths, such as 6 inches, 12 inches, or 24 inches. The ruler is used as a reference edge for measurements and can be affixed to either the square head or the center head.

- Square Head: The square head is an attachment that has a right angle and can slide along the ruler. This tool is utilized to verify or indicate 90-degree angles. The square head on a ruler often includes a locking mechanism that allows it to be securely positioned at a specific location. Additionally, it can be easily adjusted to measure depth, which proves to be useful for tasks such as setting the depth of a saw blade or drill bit.

- Center Head: The center head, which is also referred to as the protractor head, is an attachment that is designed to move and rotate freely around the ruler. The tool is mainly utilized for marking or measuring angles that are not 90 degrees, such as 45-degree angles. The center head often includes a protractor scale, which allows for precise angle measurement.

How to Use a Combination Square for Measuring and Marking

Using a combination square is a simple process that can be broken down into the following steps:

- Select the Desired Function: Depending on the specific task at hand, determine whether it is necessary to utilize the square head or the center head.

- Adjust the Position: To position the chosen head, slide it along the ruler to the desired location. If needed, secure it in place by utilizing the locking mechanism.

- Place the Combination Square: Place the combination square on the workpiece, ensuring that the head is securely positioned against the edge. Make sure that the ruler is parallel to the surface you are measuring or marking.

- Take Measurements or Make Marks: To ensure squareness (90 degrees), utilize the square head. Alternatively, employ the center head to measure or mark angles as required. To ensure accuracy, double-check the square or angle before making any cuts or marks.

- Adjust Depth (if required): To set an appropriate depth for your task, simply adjust the square head accordingly. This feature is especially handy for tasks such as adjusting the depth of a saw blade or accurately marking hole depths.

By following these steps, you can transform a combination square into a valuable tool that guarantees precision and accuracy in your measurements and layout work.

What is a Double Square?

A double square is a precision measuring tool specifically designed to provide accurate right angles and perpendicular measurements. The object is composed of two square heads that are connected at a 90-degree angle, creating a T-shape. The double square is primarily designed to ensure precise right angles, unlike the combination square which offers versatility in measuring various angles.

Features and Components of a Double Square

Typically, a double square consists of various components and features, which may include:

- Two Square Heads: The distinguishing characteristic of a double square is its two square heads, which are positioned at a right angle to each other. The square heads have been precision-ground to guarantee that the angle between them is precisely 90 degrees.

- Adjustable Heads: Certain double squares have adjustable square heads, which enable you to make precise adjustments to the right angle if needed.

- Ruler or Beam: Similar to a combination square, a double square can also feature a ruler or beam that connects the two square heads. A ruler is used as a reference edge for measurements and can come in various lengths to suit different tasks.

- Locking Mechanism: Certain double squares are equipped with a locking mechanism that effectively holds the square heads at a precise angle, providing enhanced stability while in use.

Advantages of a Double Square over Other Measuring Tools

Although a double square may appear to be more specialized when compared to versatile tools like a combination square, it actually provides several advantages in specific situations.

- Unmatched Right Angles: The main advantage of a double square is its capability to ensure precise 90-degree angles. Precise right angles are of utmost importance in fields such as machining, metalworking, and woodworking. This is crucial for ensuring the creation of accurate and functional components.

- Perpendicular Measurements: Double squares are excellent tools for making perpendicular measurements. This technique is especially useful for aligning and squaring machinery, ensuring the accuracy of square assemblies, and verifying that joints or edges are perfectly perpendicular.

- Simplicity and Precision: Double squares are specifically designed for one purpose: to ensure the accuracy of right angles. The exceptional precision is a result of this simplicity. Unlike combination squares, which require the user to align and lock the square head, a double square has a fixed 90-degree angle that eliminates any possibility of error.

- Durability and Reliability: Double squares of high quality are typically constructed to be durable, featuring square heads crafted from hardened steel and other sturdy materials. These products are designed to last a long time and provide consistent accuracy.

- Complementary Tool: A double square can be a valuable addition to your toolkit, complementing the functionality of a combination square. Although a combination square is versatile, a double square is an ideal tool for achieving precise 90-degree angles.

To summarize, a double square is a specialized tool that is perfect for tasks requiring accurate right angles and perpendicular measurements. Its unwavering commitment to accuracy makes it an invaluable tool in industries where precision is of utmost importance.

Combination Square vs. Double Square

When making a decision between a combination square and a double square, it is crucial to have a clear understanding of the distinctions between these two measuring tools in various important aspects:

1. Purpose and Primary Use of Each Tool

Combination Square:

- Purpose: The primary purpose of a combination square is to provide versatility. The tool is capable of measuring and marking different angles, such as 90 degrees and 45 degrees, which makes it highly versatile for a variety of tasks.

- Primary Use: Angles, lines, and squareness are commonly measured, marked, and checked in woodworking, metalworking, construction, and general DIY projects.

Double Square:

- Purpose: The main function of a double square is to guarantee the precision of 90-degree angles. It is highly proficient in creating and verifying precise right angles and perpendicular lines.

- Primary Use: The tool is primarily utilized in precision metalworking, machining, and woodworking tasks that require precise squareness. It is commonly used for setting up machinery, ensuring squareness in assemblies, and aligning components.

2. Accuracy and Precision Differences

Combination Square:

While it offers a high level of accuracy for most tasks, it may not be as precise as a double square when it comes to verifying 90-degree angles.

Double Square:

This tool is known for its exceptional accuracy and precision when it comes to measuring 90-degree angles. It is the preferred choice when absolute squareness is crucial. The fixed 90-degree angle ensures there is no room for error.

3. Versatility and Adaptability in Various Tasks

Combination Square:

- The tool is highly versatile because it can accurately measure and mark a wide range of angles.

- This tool is ideal for tasks that require working with angles other than 90 degrees or when you need a versatile tool that can perform multiple functions.

Double Square:

- This tool is designed specifically to ensure precise right angles, making it perfect for applications that require squareness to be of utmost importance.

- It is not as versatile when it comes to measuring angles that are not 90 degrees.

4. Cost Considerations

Combination Square:

- Combination squares are generally less cost-effective.

- It offers a great balance between functionality and price, making it accessible to a wide range of users.

Double Square:

- The cost of this product is typically higher because it requires precision and specialized expertise.

- This investment is ideal for professionals and serious hobbyists who demand precise right angles with absolute accuracy.

5. User-Friendliness and Ease of Use

Combination Square:

- The software is designed to be user-friendly and can be applied in various contexts.

- To achieve perfect squareness, it may be necessary to take additional steps, such as ensuring careful alignment and securely locking the components in place.

Double Square:

- This tool is highly user-friendly and ensures precise 90-degree angles.

- This method provides a simpler and more reliable way to achieve squareness.

Why Do I Need a Combination Square?

The combination square is an essential tool in a wide range of industries and DIY projects due to its versatility. The combination square excels in various practical applications and scenarios. Here are a few examples:

1. Carpentry and Woodworking:

- Measuring and Marking: Combination squares are commonly utilized for accurately measuring and marking precise lengths and angles on wooden boards. These tools assist woodworkers in achieving precise cuts for joints, bevels, and angles.

- Checking Squareness: Combination squares are essential tools for woodworkers as they help verify the squareness of corners and edges. By using combination squares, woodworkers can ensure that furniture pieces and cabinets are perfectly square.

- Setting Blade Heights: Combination squares are a useful tool for accurately setting the height of cutting tools such as saw blades and router bits.

2. Metalworking and Machining:

- Layout Work: Combination squares are essential tools in metalworking and machining for layout work. These tools assist machinists in accurately marking and measuring specific positions for holes, slots, and other machining tasks.

- Checking Right Angles: It is crucial to ensure that metal components are perfectly aligned at right angles in order to achieve accurate fabrication. Combination squares are commonly employed in metalworking projects to verify squareness.

- Setting Machine Tools: Combination squares are utilized by machinists to establish the squareness and alignment of machine tools such as milling machines and lathes.

3. Construction and Home Improvement:

- Framing and Layout: Combination squares are a useful tool for various framing tasks. They can be used to mark stud locations, measure lumber for cuts, and ensure square corners in building projects.

- Tile and Flooring Installation: Combination squares are commonly used by home improvement enthusiasts to make accurate markings for tile and flooring cuts, particularly in corners and along walls.

- Plumbing and Electrical Work: Combination squares are useful tools for layout work in plumbing and electrical installations. They help ensure that pipes and conduits are accurately positioned.

Benefits of Using a Combination Square for Accuracy and Efficiency

Using a combination square provides numerous benefits that enhance both the accuracy and efficiency of your work.

- Precision: Combination squares are a useful tool for obtaining precise measurements, enabling you to achieve tight tolerances and perfect angles. This level of precision helps to minimize errors and guarantees that your cuts and marks are accurate.

- Time Savings: The combination square is a versatile tool that allows you to efficiently measure, mark, and check angles, eliminating the need for multiple tools. Streamlining your workflow and saving valuable time on projects is one of the key benefits of this approach.

- Versatility: Combination squares are highly versatile tools due to their ability to accurately measure and mark various angles, such as 90 degrees and 45 degrees. This versatility makes them suitable for a wide range of tasks. You do not need to use multiple tools for different angles.

- Ease of Use: Combination squares are designed to be user-friendly and require only minimal training. The ruler’s clear markings and square head locking mechanisms make it easy to use, even for beginners.

- Quality Assurance: The use of a combination square can greatly improve the quality of your work. Using it helps you maintain consistent measurements, ensuring that the components of your project fit together precisely.

- Cost-Efficiency: Combination squares provide great value for the price. These tools are both affordable and versatile, making them a cost-effective addition to your toolkit.

Why Do I Need a Double Square?

The double square, with its specialized design that guarantees perfect right angles, provides distinct advantages in certain situations.

1. Precision Layout and Measurement in Tight Spaces

- Double squares are particularly useful in confined or tight spaces where the use of traditional measuring tools can be challenging. The compact T-shape design enables precise maneuverability in tight spaces, including corners and crevices.

- Double squares are frequently used by machinists and metalworkers to set up machinery in compact workshops where space is limited.

2. Ensuring Perpendicular and Parallel Lines

- Double squares are unmatched when it comes to confirming perpendicularity. A double square is a reliable tool for ensuring that your lines are perfectly at right angles, whether you are aligning components, checking the squareness of joints, or verifying the straightness of an edge.

- A double square is essential in applications where parallel lines are crucial, such as aligning rails or tracks. It ensures precise and uniform spacing.

How a Double Square Can Complement a Combination Square in Your Toolkit

Combination squares are known for their versatility and ability to handle various tasks. However, it is worth considering adding a double square to your toolkit as well. This addition can greatly enhance your measuring and layout capabilities in specific ways.

- Precise Right Angles: A double square provides unparalleled accuracy when confirming or creating perfect right angles. You can utilize it to verify the squareness of your workpieces, machinery, or assemblies.

- Narrow Spaces: When faced with tight spaces that make it difficult to use a combination square effectively, a double square’s compact design is the perfect solution. It enables you to maintain accuracy while measuring or marking in constrained areas.

- Specialized Projects: A double square is essential for projects that require exceptional precision and squareness, such as fine cabinetry, metal fabrication, or high-precision machining. It guarantees that your work meets the strictest standards.

- Comprehensive Toolkit: Including both a combination square and a double square in your toolkit allows you to effectively handle a wider range of tasks. The combination square is ideal for measuring angles in a versatile manner, while the double square is perfect for ensuring precise right angles.

- Quality Control: Integrating a double square into your workflow is akin to having an inherent quality control mechanism. It enables you to verify and validate the precision of your work, guaranteeing that all components align flawlessly.

Wrapping up

This article delves into the differences between combination squares and double squares, which are both important tools used for precise measurements. Here is a summary of the main points of comparison:

Purpose and Primary Use:

- Combination Square: This tool is versatile and can be used to measure and mark various angles, including 90 degrees and 45 degrees.

- Double Square: This tool is designed specifically to ensure accurate 90-degree angles and perpendicular lines.

Accuracy and Precision:

- Combination Square: It is highly accurate for most tasks, although it may not achieve the same level of precision as a double square when it comes to creating perfect right angles.

- Double Square: Experience unparalleled accuracy and precision when measuring 90-degree angles.

Versatility and Adaptability:

- Combination Square: This tool is versatile and adaptable, making it suitable for a wide range of tasks and angles.

- Double Square: Designed specifically for right angles, this feature limits its versatility but makes it perfect for specific applications.

Cost Considerations:

- Combination Square: It is generally more affordable and provides good value due to its versatility.

- Double Square: It is generally more expensive because of its precision and specialized nature, making it a worthwhile investment for professionals.

User-Friendliness:

- Combination Square: The product is designed to be user-friendly and is well-suited for beginners.

- Double Square: The product is highly user-friendly, especially when it comes to ensuring right angles.

Combination Square:

- Perfect for carpentry, woodworking, construction, and various DIY projects.

- Measuring and marking various angles is made easier and more accurate with the use of this valuable tool.

- This tool is helpful for verifying squareness and determining the appropriate cutting tool depths.

- The product is versatile and cost-effective.

Double Square:

- Precision metalworking, machining, and fine woodworking all require essential skills.

- This tool guarantees precise right angles and perpendicular lines.

- Excels in confined spaces and busy work environments.

- We offer unparalleled precision in handling specialized projects.

In summary, the decision between a combination square and a double square depends on the specific needs of your projects and the level of accuracy you require. Both tools have their own strengths and are valuable assets to any toolkit. When making your selection, it is important to consider the nature of your tasks, the angles that you need to measure, and your budget. By selecting the appropriate tool for the task at hand, you can improve the precision and effectiveness of your work, guaranteeing that your projects adhere to the utmost standards of quality and skill.