Exploring Bandsaw Alternatives: A Comprehensive Guide for Woodworkers

Bandsaws have always been a popular tool in woodworking and metalworking shops due to their versatile cutting capabilities. These power tools have a smooth and efficient cutting mechanism that ensures precise cuts on a variety of materials. When it comes to woodworking, bandsaws are perfect for tasks such as transforming thick boards into thinner pieces, creating intricate curves, and cutting lumber to the desired size. Bandsaws are essential tools for metalworkers, serving a variety of purposes including cutting metal stock, shaping metal components, and even adding intricate detailing.

However, even though bandsaws can be quite useful, they may not always be the ideal choice for every workshop or project. For various reasons, craftsmen who work with wood or metal sometimes need to explore alternatives to the conventional bandsaw. This could be due to budget limitations, space constraints, or specific project needs.

Let’s explore a variety of tools that can be used as alternatives to a bandsaw for different tasks. We will explore the advantages and disadvantages of both manual and powered saws, assisting you in selecting the ideal tool for your workshop requirements. Whether you’re an experienced craftsman seeking to enhance your collection of tools or a casual hobbyist with limited space, this guide will provide you with the information you need to make well-informed choices about your cutting tools. Let’s delve into the realm beyond the bandsaw and uncover the various tools that can enhance your woodworking and metalworking endeavors.

Understanding Bandsaw Functions

In any woodworking or metalworking shop, the bandsaw is a versatile tool that can perform a wide range of tasks with precision and efficiency. In order to fully grasp the significance of bandsaw alternatives, it is crucial to have a deep understanding of the fundamental functions that make the bandsaw an essential tool in any workshop.

Resawing

The bandsaw is exceptional at resawing lumber, effortlessly and precisely turning thick boards into thinner pieces. If you want to make the most of your wood and create precise cuts for detailed projects, the bandsaw’s vertical blade orientation is perfect. It can effortlessly cut through even the toughest hardwoods, giving you smooth and uniform results.

Cutting Curves

The bandsaw is incredibly skilled at cutting curves with unmatched precision, from gentle arcs to intricate scrollwork. The bandsaw blade’s seamless loop and exceptional maneuverability make it the ideal tool for crafting intricate designs and complex profiles. Whether you’re engaged in crafting furniture, fashioning decorative accents, or designing custom trim pieces, the bandsaw’s curved cutting capabilities offer a multitude of creative opportunities.

Ripping Lumber

The bandsaw is not only skilled in curved cutting but also excels at ripping lumber. Although table saws are commonly used for this job, bandsaws have their own set of benefits, especially when working with oddly shaped or larger pieces of material. The vertical blade orientation of the bandsaw provides enhanced stability and control, resulting in smoother cuts and a lower risk of kickback.

With its mastery of these essential functions, the bandsaw has become a vital tool in woodworking and metalworking shops worldwide.

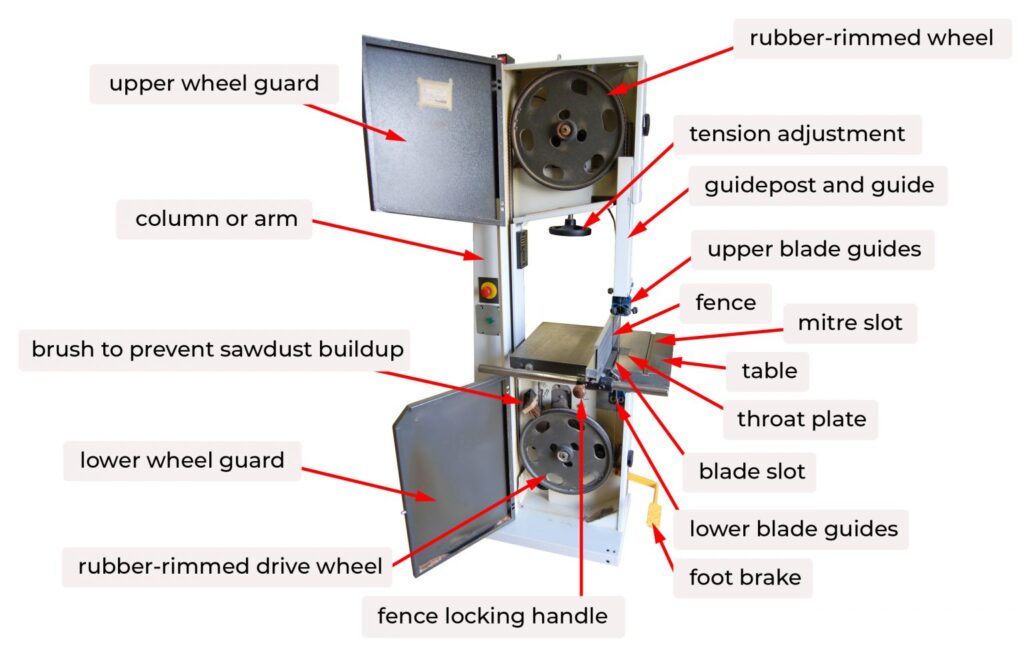

Image: pressbooks.bccampus.ca

Reasons for Seeking Bandsaw Alternatives

Although the bandsaw is widely favored in woodworking and metalworking shops, there are several reasons why craftsmen and hobbyists may consider exploring alternative tools. Now, let’s delve into the main reasons why people seek alternatives to bandsaws:

1. Cost

Price plays a crucial role for woodworkers and metalworkers when they contemplate buying tools. High-quality bandsaws, with their advanced features, can be quite an investment. For individuals who prefer a more budget-friendly approach or want to invest their funds in other areas of their workshop, considering alternative tools that provide comparable functionality at a more affordable price can be quite enticing.

2. Space Limitations

In workshops where space is limited, accommodating bulky stationary tools like bandsaws can be quite a task. Bandsaws usually take up a significant amount of space, needing their own designated area and sometimes extra room for moving materials. In smaller workshops or shared garage spaces, the desire to make the most of limited space may lead craftsmen to look for alternative tools that provide similar functionality in a more compact size.

3. Specific Project Requirements

Although the bandsaw is highly versatile for various cutting tasks, there are specific projects where alternative tools may provide unique benefits. Take, for instance, the intricate fretwork or delicate scrollwork that can greatly benefit from the precision and maneuverability of a scroll saw. Similarly, different materials or cutting techniques may be more suitable for alternative tools. For instance, you could use a router to create intricate profiles or a hand saw for fine detail work.

Hand Saw Alternatives

Although power tools like the bandsaw are known for their speed and efficiency, there is an enduring charm in the meticulous craftsmanship and precision of hand saws. When it comes to cutting curves, hand saws offer a close connection to the workpiece, enabling precise control and finesse. Discovering popular alternatives to the bandsaw and the specific situations where they shine:

Coping Saws

Coping saws are a timeless option for effortlessly cutting intricate curves and detailed patterns in wood. Coping saws are great at maneuvering through tight turns and intricate contours with their thin, narrow blades and fine teeth. Woodworkers frequently rely on coping saws for various tasks such as cutting dovetail joints, shaping cabriole legs, or crafting intricate scrollwork. These tools are perfect for delicate tasks in tight areas or on complex projects that require careful handling.

Frame Saws

Frame saws, also called bow saws, are great for cutting curves in thicker stock or rough lumber due to their larger cutting capacity compared to coping saws. Frame saws are versatile tools that can effortlessly handle a range of materials, including hardwoods, softwoods, and plastics. Woodworkers often opt for a frame saw to accomplish various tasks, such as resawing large boards into thinner pieces, shaping curved components for furniture, or cutting out rough profiles for carving. With the right blade, a frame saw can effortlessly achieve precise, smooth cuts, making it a versatile tool for various woodworking projects.

Scenarios for Each Type

The scenarios where each type of hand saw would be most effective

- Coping Saws: Coping saws are perfect for tasks that demand precise craftsmanship, like cutting out intricate scrollwork, shaping detailed joinery, or trimming curved moldings.

- Frame Saws: Frame saws are perfect for tasks that require cutting curves in thicker stock or rough lumber. They are great for resawing boards, shaping curved components for furniture, or cutting out rough profiles for carving.

Woodworkers can hand-pick the apt tool for the job, whether it involves intricate scrollwork or heavy-duty resawing, by recognizing the advantages and drawbacks of each hand saw option.

Powered Saw Alternatives

Woodworkers and metalworkers have a wide range of alternatives to the bandsaw when it comes to powered saw options. Now, we can delve into a few well-liked alternatives and their distinct benefits:

Scroll Saws

Scroll saws are well known for their exceptional ability to create intricate cuts with accuracy and elegance. Unlike bandsaws, scroll saws have a thin, narrow blade that moves up and down in a reciprocating motion. This design is perfect for tight turns and intricate detailing, making scroll saws a great choice for delicate scrollwork, fretwork, and decorative designs. When it comes to woodworking, scroll saws are a fantastic choice. They provide excellent blade control and maneuverability, making them perfect for tackling intricate projects.

Jigsaws

Jigsaw tools are incredibly versatile and are especially adept at cutting curves and irregular shapes. Jigsaws are perfect for cutting tasks on-site or in small workspaces due to their compact size and handheld design. They offer portability and flexibility, making them a great choice for those who need a versatile tool. Jigsaws offer the flexibility of freehand cutting, making them a versatile tool for various applications such as shaping furniture components or trimming laminate countertops. Jigsaws are incredibly versatile tools that woodworkers and DIY enthusiasts find indispensable. With the ability to easily change blades and adjust cutting angles, they offer a level of convenience that is hard to beat.

Table Saws

Table saws are commonly used for straight-line cutting tasks, but they can also be a great option for ripping lumber, making them a versatile alternative to bandsaws. With the right jigs and accessories, woodworkers can achieve comparable results to bandsaws using a table saw, although there are a few limitations to keep in mind. Take, for instance, a table saw that comes with a rip fence and feather boards. With this setup, you can effortlessly and precisely rip narrow stock or resaw thick boards into thinner pieces. Although bandsaws are more flexible and maneuverable for curved cutting tasks, table saws excel in their cutting capacity and stability, making them ideal for large-scale projects or production work.

When exploring different options for powered saws, it’s important to carefully consider the advantages and limitations of each choice, taking into account your specific project requirements and workshop setup. There are various powered saw options available to meet your woodworking and metalworking needs, whether you prefer the accuracy of a scroll saw, the flexibility of a jigsaw, or the cutting power of a table saw. Try out various tools, refine your skills, and find the ideal solution for your next cutting job.

Alternative Cutting Methods

Although saws are commonly used for cutting tasks in woodworking and metalworking, there are other methods that can produce exceptional results, especially for specific applications or unique project needs. Let’s delve into some alternative options that provide innovative solutions to cutting obstacles:

Using a Router for Creating Curves

Routers are incredibly versatile tools that are frequently employed for shaping edges, cutting grooves, and crafting intricate profiles in various materials. Although not typically associated with cutting curves, routers can actually be quite effective in this regard when paired with the appropriate accessories. Using a router equipped with a template guide and either a flush-trim bit or a spiral upcut bit, woodworkers can effortlessly create seamless and accurate curves in a wide range of materials. With the help of templates or guides, craftsmen can effortlessly recreate intricate shapes using routers, making them an excellent choice for curved cutting tasks.

Using a Drill Press for Interior Cuts

Drill presses are reliable machines in the workshop, valued for their precision and flexibility in drilling holes of different dimensions and depths. Drill presses are not limited to drilling alone; they can also be utilized for cutting tasks, especially when it comes to making precise interior cuts in workpieces. Woodworkers can achieve precise cuts with controlled depth and accuracy by mounting a spiral saw attachment or a rotary tool like a Dremel in the drill press’s chuck. This setup is great for creating detailed inlays, carving recesses for hardware, or making precise interior cuts in panels or tabletops.

Benefits of Alternative Cutting Methods

- Precision: Other cutting techniques provide precise and accurate results, enabling woodworkers to achieve intricate details and tight tolerances in their projects.

- Versatility: Craftsmen can enhance the versatility of their workshop by utilizing routers and drill presses for cutting tasks, enabling them to take on a diverse array of projects without requiring specialized equipment.

- Creative Freedom: Exploring alternative cutting methods allows woodworkers to unleash their creativity and experiment with innovative techniques, pushing the boundaries of traditional woodworking and metalworking.

By incorporating different cutting methods into their workflow, craftsmen can broaden their range of techniques and achieve exceptional results in their projects. Exploring unconventional techniques and tools can result in one-of-a-kind creations that are both inspiring and innovative.

Safety Considerations

When it comes to working with cutting tools, it’s crucial to prioritize safety above all else. Whether you’re using a traditional bandsaw, exploring alternative cutting methods, or working with hand tools, it’s crucial to prioritize safety practices to ensure the well-being of yourself and others in the workshop. Now, let’s explore some important safety factors and basic tips that are relevant to the alternatives we’ve been discussing:

Importance of Safety when using any cutting tool

Using sharp tools carries inherent dangers, such as the possibility of cuts, lacerations, and other significant injuries. These tools require careful handling and attention, as they can be quite dangerous. By emphasizing safety and following established guidelines, craftsmen can reduce the chances of accidents and create a secure and efficient workspace.

Basic Safety Tips

- Wear Personal Protective Equipment (PPE): Make sure to always wear the necessary personal protective equipment (PPE) to keep yourself safe. This includes safety glasses or goggles to shield your eyes from any potential flying debris, hearing protection to minimize exposure to loud noise, and gloves to enhance your grip and safeguard against sharp edges.

- Secure Workpieces Properly: Make sure to firmly secure workpieces before cutting to avoid any shifting or movement during the operation.

- Use Push Sticks and Guides: When operating power tools such as routers or drill presses, it’s important to prioritize safety. To ensure your hands stay a safe distance from the cutting area and maintain control over the workpiece, make use of push sticks, guides, or other accessories.

- Keep Hands Clear of Blades: Always exercise caution when working with blades, such as hand saws, router bits, or drill presses, to avoid any potential accidents. Make sure to wait for the blade to fully stop before making any adjustments or handling the workpiece.

- Follow Manufacturer’s Guidelines: It’s important to adhere to the manufacturer’s instructions and guidelines when using and caring for your tools. Take the time to acquaint yourself with the tool’s safety features, proper usage, and maintenance procedures to guarantee a secure and effective operation.

- Maintain a Clean and Organized Workspace: Maintain a tidy workshop to reduce the risk of accidents and create a safe environment for using cutting tools.

- Stay Focused and Alert: Stay attentive and concentrate on the task at hand when using cutting tools. It is important to avoid operating machinery while under the influence of alcohol or drugs, as impaired judgment can increase the risk of accidents.

By adhering to these essential safety guidelines and staying alert in the workshop, craftsmen can establish a secure and protected setting for themselves and those around them. Just a friendly reminder to prioritize safety when engaging in woodworking and metalworking. It’s important to take proactive steps to minimize risks and ensure a satisfying and safe experience.

Cost Analysis

When it comes to investing in tools for your workshop, price is an important aspect to take into account. Although the bandsaw is a must-have tool for woodworkers and metalworkers, it’s worth considering other options that can provide similar functionality at a lower cost. Now, let’s take a look at the expenses involved in buying and upkeeping a bandsaw compared to other options:

Purchasing Costs

Bandsaw:

- Bandsaws are available in various sizes, features, and price ranges. You can find basic benchtop models starting at around $200 to $300, while industrial-grade floor-standing models can cost $1,000 or more.

- Top-of-the-line bandsaws offer a range of impressive features like adjustable speed, generous cutting capacities, and durable build quality, making them a valuable addition to any workshop.

Alternatives:

- Hand saws and non-powered cutting tools are generally more affordable than bandsaws, with basic models starting at around $20 to $50.

- There are different options available for powered alternatives like scroll saws, jigsaws, and routers. Entry-level models for hobbyists start at around $100 to $200, while higher-end models for professionals can cost several hundred dollars or more.

Maintenance Costs

Bandsaw:

- Bandsaws need to be regularly maintained in order to achieve the best performance and ensure they last a long time. These tasks involve adjusting the blade tension, aligning the blade, lubricating it, and occasionally replacing the blade.

- Blades for bandsaws come in a variety of prices, depending on factors such as size, type, and quality.

Alternatives:

- Hand saws and non-powered cutting tools typically need very little maintenance apart from occasional sharpening or blade replacement, which can be done at a low cost.

- Alternative power options may require some maintenance, such as replacing blades or keeping accessories in good condition. The overall cost of maintenance can vary depending on the tool and how often it is used.

Cost-Effectiveness Considerations

Although the initial price tag of a bandsaw may appear intimidating, it’s important to take into account the lasting worth and return on investment that this versatile tool offers. For those who appreciate the precision and craftsmanship of woodworking and metalworking, the bandsaw is an invaluable tool that enhances productivity, efficiency, and versatility.

For those who enjoy hobbies, or DIY projects, or have a limited budget, considering alternative tools can provide affordable options that still deliver excellent quality and performance. By thoroughly assessing your workshop needs, project requirements, and budgetary considerations, you can make well-informed decisions about which tools provide the greatest value for your particular circumstances.

Ultimately, whether you decide on a bandsaw or explore other cutting techniques, it’s important to invest in tools that align with your requirements, elevate your abilities, and empower you to pursue your love for woodworking and metalworking with assurance and ingenuity.

Space and Convenience

When it comes to woodworking and metalworking, the layout of your workshop and how you use the space are extremely important. The dimensions, arrangement, and ease of use of tools are crucial factors in determining their compatibility with a particular work area. Now, let’s delve into how each alternative to the bandsaw can be incorporated into a workshop in various ways, taking into account factors like size, setup simplicity, and convenience:

Bandsaw:

- Size: Bandsaws come in a variety of sizes, from small benchtop models to larger floor-standing units. Although benchtop bandsaws are compact, floor-standing models provide a larger cutting capacity and enhanced stability.

- Ease of Setup: Getting a bandsaw up and running requires putting the machine together, fine-tuning the blade tension, and making sure the blade guides are perfectly aligned. This process can take a while, especially if you’re new to using a bandsaw.

- Convenience: Once you have your bandsaw all set up, it offers a convenient and efficient way to make precise cuts. You can easily switch between different cutting tasks without wasting any time.

Hand Saw:

- Size: Hand saws are small and easy to carry, making them perfect for workshops with limited space or for woodworking tasks on the move.

- Ease of Setup: Hand saws are incredibly convenient, as they require very little setup and can be used right away. This makes them perfect for making quick cuts or for working in cramped areas where power tools might not be the best option.

- Convenience: Hand saws provide the advantage of being portable and straightforward, enabling woodworkers to handle cutting tasks without relying on electricity or spending time on setup.

Powered Saw:

- Size: There are various options available for powered saw alternatives, including scroll saws, jigsaws, and routers. These alternatives come in different sizes, ranging from compact benchtop models to larger floor-standing units. The dimensions of these tools may differ based on their intended use and cutting capabilities.

- Ease of Setup: When it comes to setting up powered saw alternatives, you’ll need to put together the machine, attach the blades or bits, and make some adjustments to ensure everything runs smoothly. Although it may require some initial time investment, the process becomes more efficient with practice.

- Convenience: Alternative options to powered saws provide the convenience of motorized cutting abilities, without the need for a large space or complicated setup like a bandsaw. These tools are incredibly versatile and user-friendly, making them valuable assets for any workshop.

When it comes to selecting tools for their workshop, woodworkers and metalworkers have a lot to consider. Factors like size, ease of setup, and convenience all come into play. Ultimately, the goal is to find the perfect tools that align with their workshop layout, workflow preferences, and project requirements. No matter the size of your workspace or your preferences, there is a bandsaw alternative that will perfectly fit your workshop and cater to the needs of any craftsman.

Pros and Cons

When it comes to selecting bandsaw alternatives, it’s crucial to carefully consider the advantages and disadvantages of each option. This will help you make well-informed decisions about which tools are most suitable for your workshop and project requirements. Now, let’s delve into the pros and cons of each option that was mentioned:

Hand Saw Alternatives:

Pros

- Portability: Hand saws are lightweight and portable, making them perfect for use in compact areas or while on the move.

- Low Cost: Hand saws are quite affordable, making them a great option for budget-conscious hobbyists and DIY enthusiasts.

- Control and Precision: Hand saws provide a level of control that allows for precise cuts and intricate detailing.

Cons

- Manual Effort: Using hand saws can be quite exhausting, especially when you have to cut for long periods of time or deal with challenging materials.

- Limited Cutting Capacity: Hand saws have certain limitations when it comes to cutting capacity and efficiency, especially when compared to powered alternatives.

- Learning Curve: Becoming proficient in the art of using hand saws for intricate cutting tasks may necessitate practice and honing of skills.

Powered Saw Alternatives:

Pros

- Speed and Efficiency: Powered saws provide a more efficient and speedy cutting experience, allowing you to finish your cutting tasks in less time.

- Versatility: Powered saws offer a wide range of cutting capabilities, allowing for both straight cuts and intricate curves. They are a versatile addition to any workshop.

- Ease of Use: Once you have everything in place, using powered saw alternatives is a breeze. They don’t demand much physical exertion like hand saws do.

Cons

- Cost: Alternative options to powered saws may come with a higher initial price tag, especially for top-of-the-line models that offer advanced features.

- Space Requirements: Certain alternatives to powered saws, like scroll saws and routers, might necessitate a designated area in the workshop, which could restrict versatility in more compact workspaces.

- Maintenance: Other options for powered saws may need regular upkeep, such as changing blades or bits, lubricating, and making adjustments, which can increase the overall expenses.

By thoughtfully weighing the advantages and disadvantages of different bandsaw options, craftsmen and artisans can make well-informed choices that suit their financial, spatial, and project-specific needs. Whether you prefer the convenience and accuracy of hand saws or the efficiency and flexibility of powered alternatives, there is a solution to suit any workshop and any craftsman’s requirements.

Read more: How To Sharpen A Circular Saw Blade By Hand?

Conclusion

Throughout our exploration of bandsaw alternatives, we have examined a wide range of tools that provide innovative solutions for both woodworking and metalworking projects. Whether you prefer the traditional hand saw or the convenience of a powered alternative, each option has its own set of advantages and factors to consider. Now, let’s quickly go over the bandsaw alternatives discussed in this article:

Hand Saw Alternatives

Coping saws and frame saws are excellent tools for cutting curves with precision and control. They are also portable and affordable, making them a great choice for hobbyists and DIY enthusiasts. Hand saws are perfect for achieving intricate detailing and fine craftsmanship, although they do require more manual effort and skill to master.

Powered Saw Alternatives

Scroll saws, jigsaws, and routers are excellent tools that provide fast, efficient, and versatile cutting capabilities for a variety of tasks. Motorized cutting tools offer enhanced productivity and user-friendly features, making them valuable assets for any workshop.

As you dive into your woodworking and metalworking projects, I suggest trying out various tools and techniques that suit your unique requirements and personal style. Whether you prefer the clean precision of hand saws or the versatility of powered alternatives, there are plenty of options to explore and discover. Embrace the chance to enhance your collection of tools, refine your abilities, and unleash your imagination in the workshop.

Just keep in mind that woodworking is all about the joy of exploring and trying new things. By embracing different cutting tools and exploring their wide range of options, you’ll discover new possibilities and enhance your craft to a whole new level. Get ready to dive into your next woodworking project with enthusiasm and creativity. It’s time to get your tools ready and let your imagination run wild. Enjoy your crafting!